From Cochlea Implant to Prosthesis and Surgical Tools

We have the competencies to handle the complete production process of a medical-technical device in a customer-specific manner and to ensure the quality of the products. We are a certified company according to EN ISO 13485, whose specifications we actively implement on a daily basis. National and international quality standards create the framework for our processes, which are regularly reviewed by external auditors.

Precision in all processes

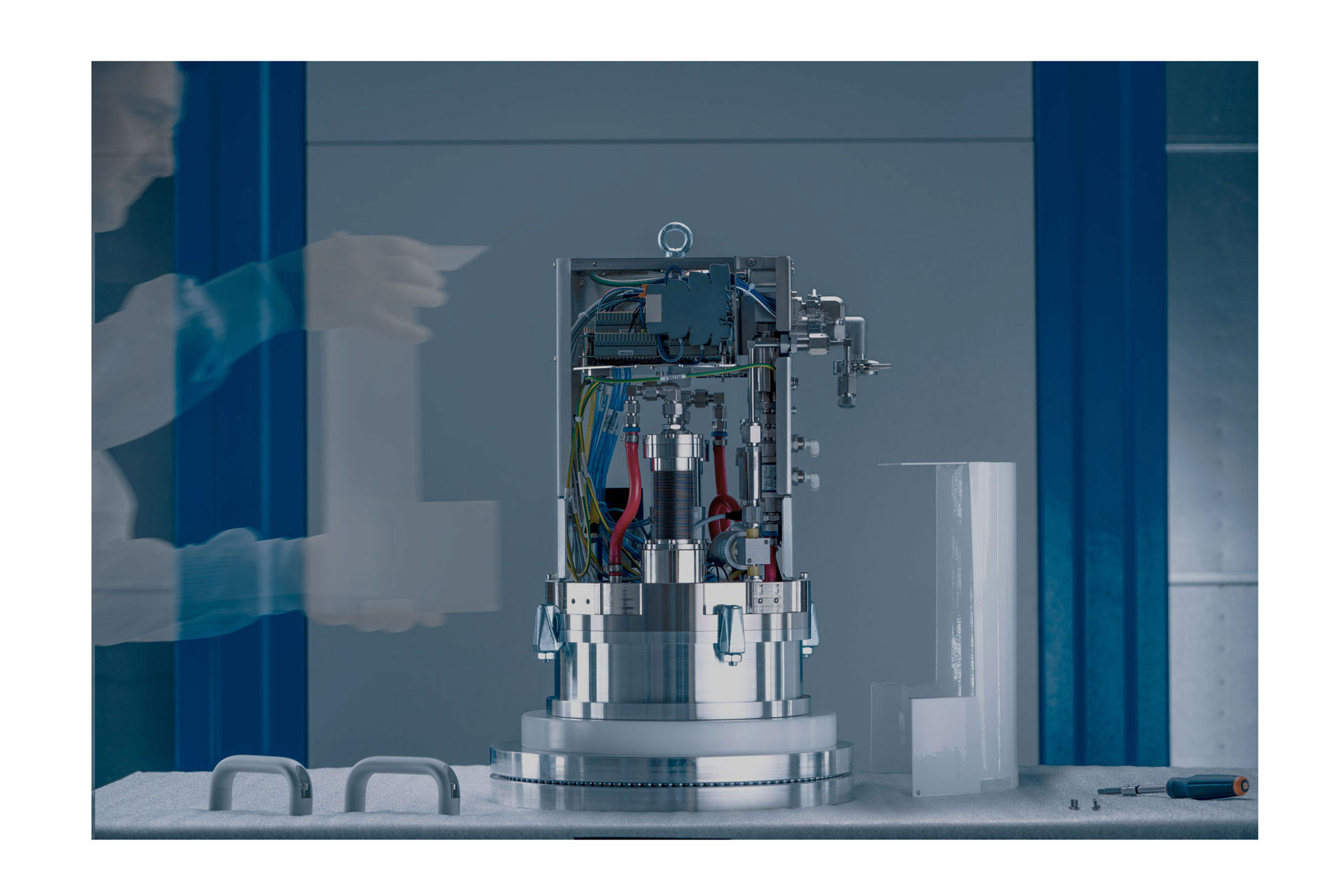

At the beginning, we determine customer requirements and certification conditions. After a detailed analysis, we combine the customer’s development expertise with our manufacturing expertise to define the best manufacturing solution. Then we fix the resources for personnel, materials, tools, testing and documentation. That followed we build the perfect prototype and the proper pilot series. Based on the findings, we adapt and optimize before transferring to series production.

The complex manufacturing process of medical devices is accompanied by accurate documentation describing the testing and production process. We also pay high attention to the use of suitable testing equipment. With established documentation and constant vigilance, our experts ensure that there is complete traceability. In this way, we create the basis for monitoring the entire production process, thereby anchoring quality management and certification measures.

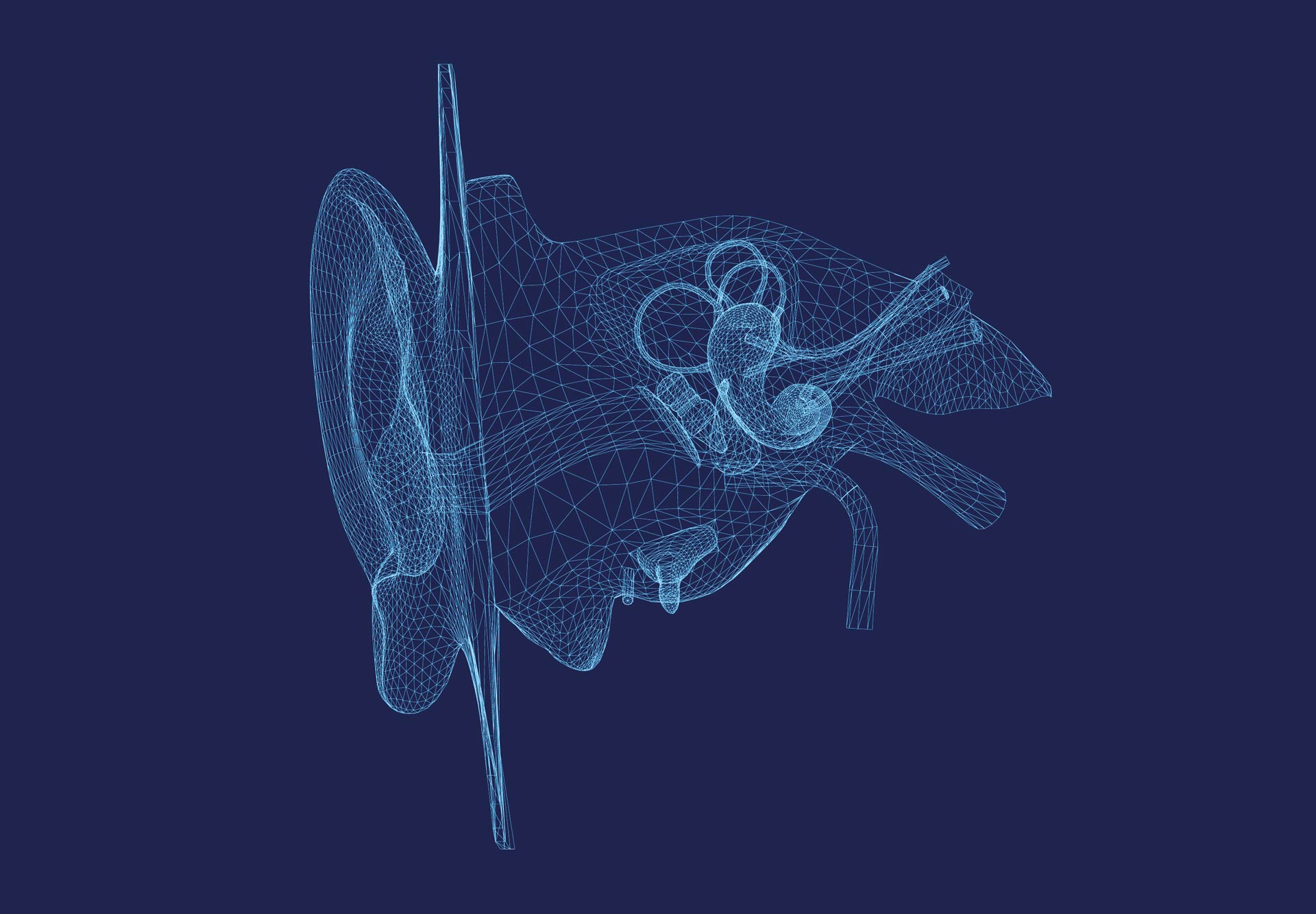

How does our experience in precision mechanics contribute to better hearing?

In order that people with severe or profound hearing loss can hear again, so-called cochlea implants are used in medical technology. They provide a bypass in the non-functioning part of the inner ear and transmit sound information directly to the auditory nerve. For this purpose, an electrode array is inserted into the cochlea during a surgical procedure. An audio processor captures the sound signals and sends them to the implant, which is embedded under the skin behind the ear.

Innovative solutions for the global industry leader

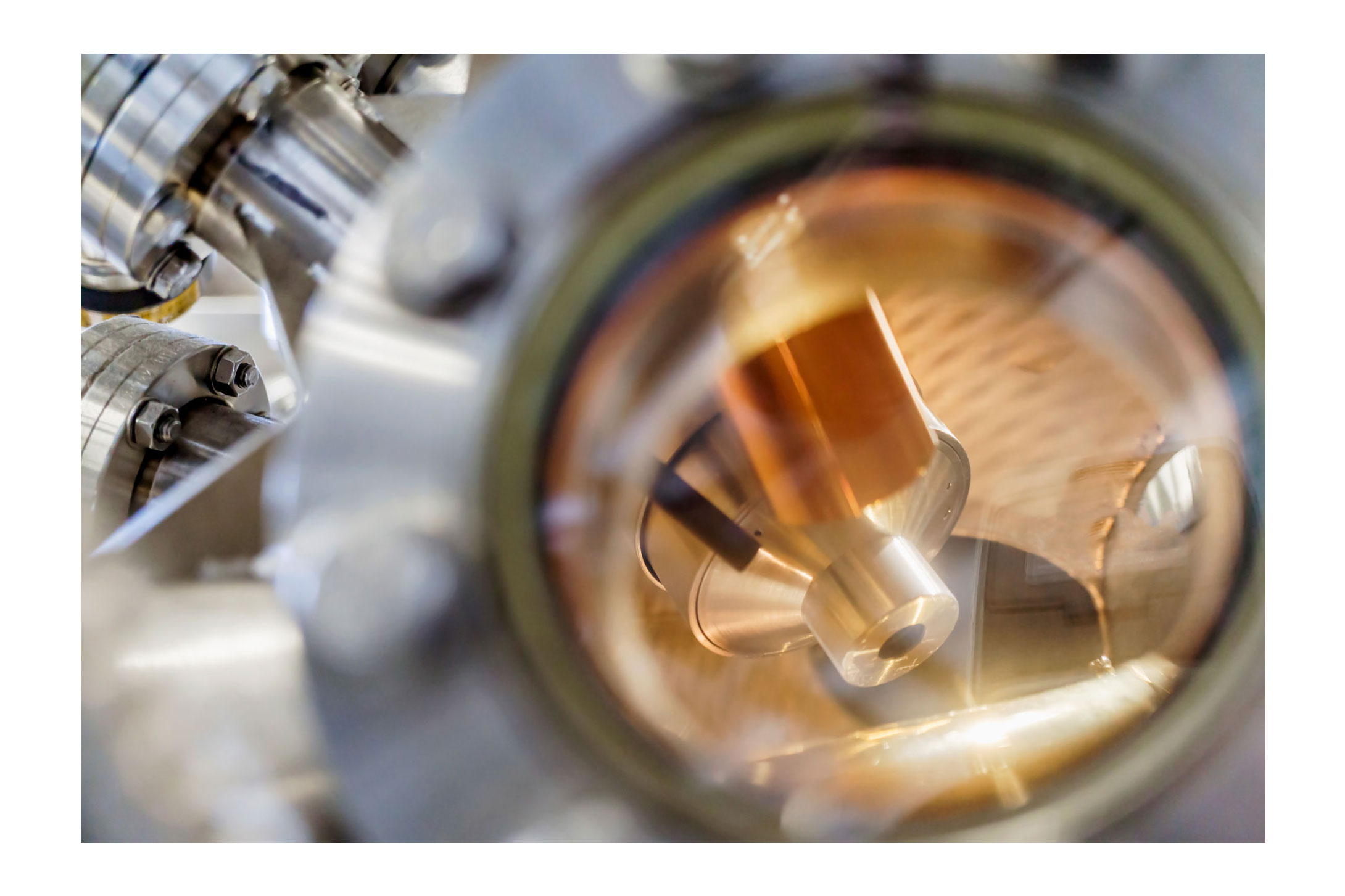

Our client, a technology leader in implantable hearing solutions, develops and manufactures cochlea implants. They are only a few millimeters in size and are true marvels of microelectronics. So that these can be produced in series, our knowhow is also required. Together with our customer, we develop various manufacturing devices for the production of implantable electrodes and housings. Not only the requirements for the surface quality are very high – they also call for cutting-edge coating technologies for good demoldability and a long service life. In addition, these tiny electrodes require high contour fidelity. This again requires special tooling technologies.

The creativity of our experts in defining special manufacturing strategies is also important. The lively exchange of information and the cooperative partnership with our customer’s designers and developers have contributed significantly to our success.