Cleaning

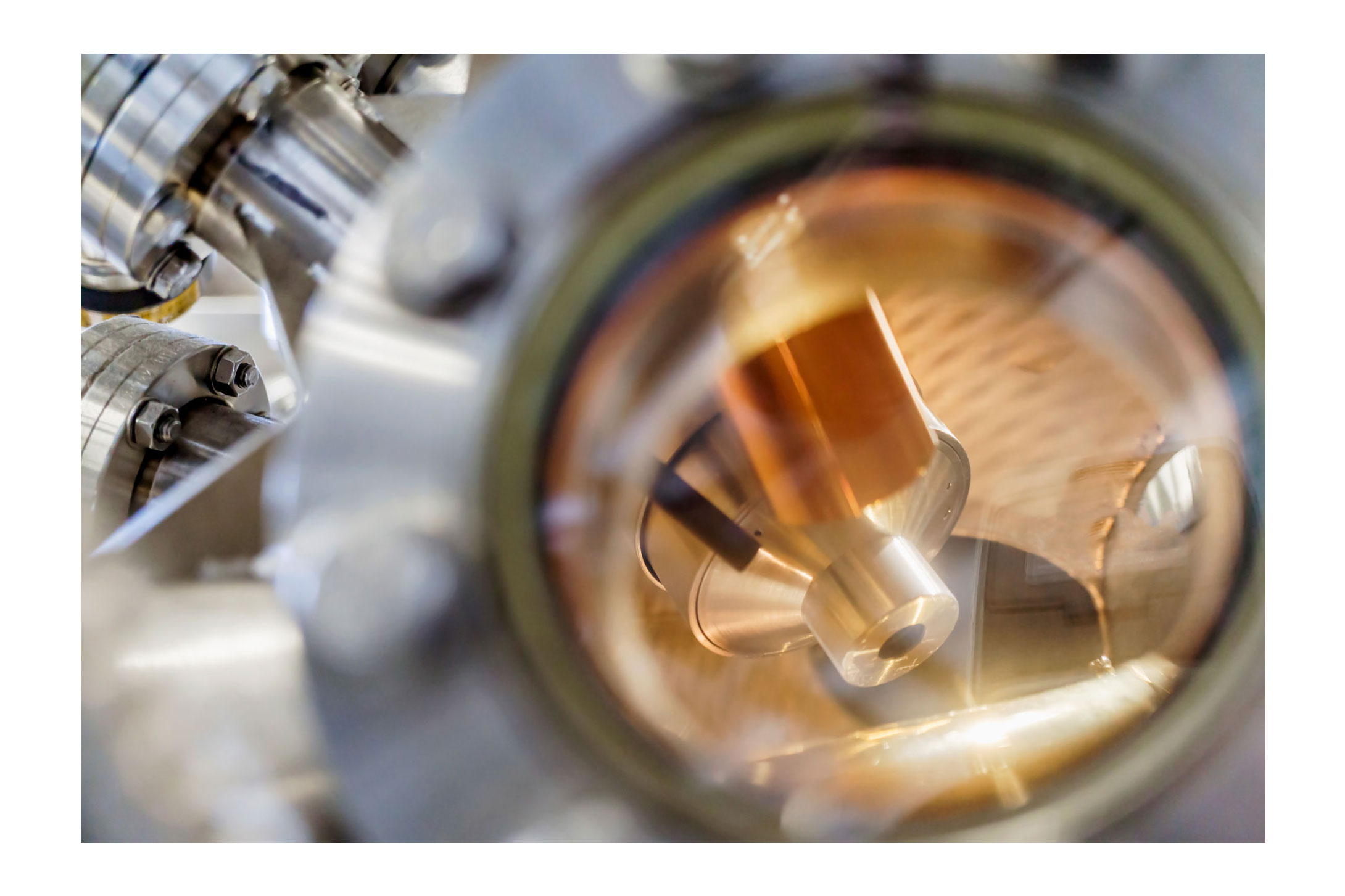

Clean surfaces are a basic requirement in our target markets. Therefore, the requirements for the cleanliness of the manufactured components and assemblies are very high. All contaminants shall be removed from the surfaces so that they do not desorb under vacuum conditions and create gas loads or deposit on internals.

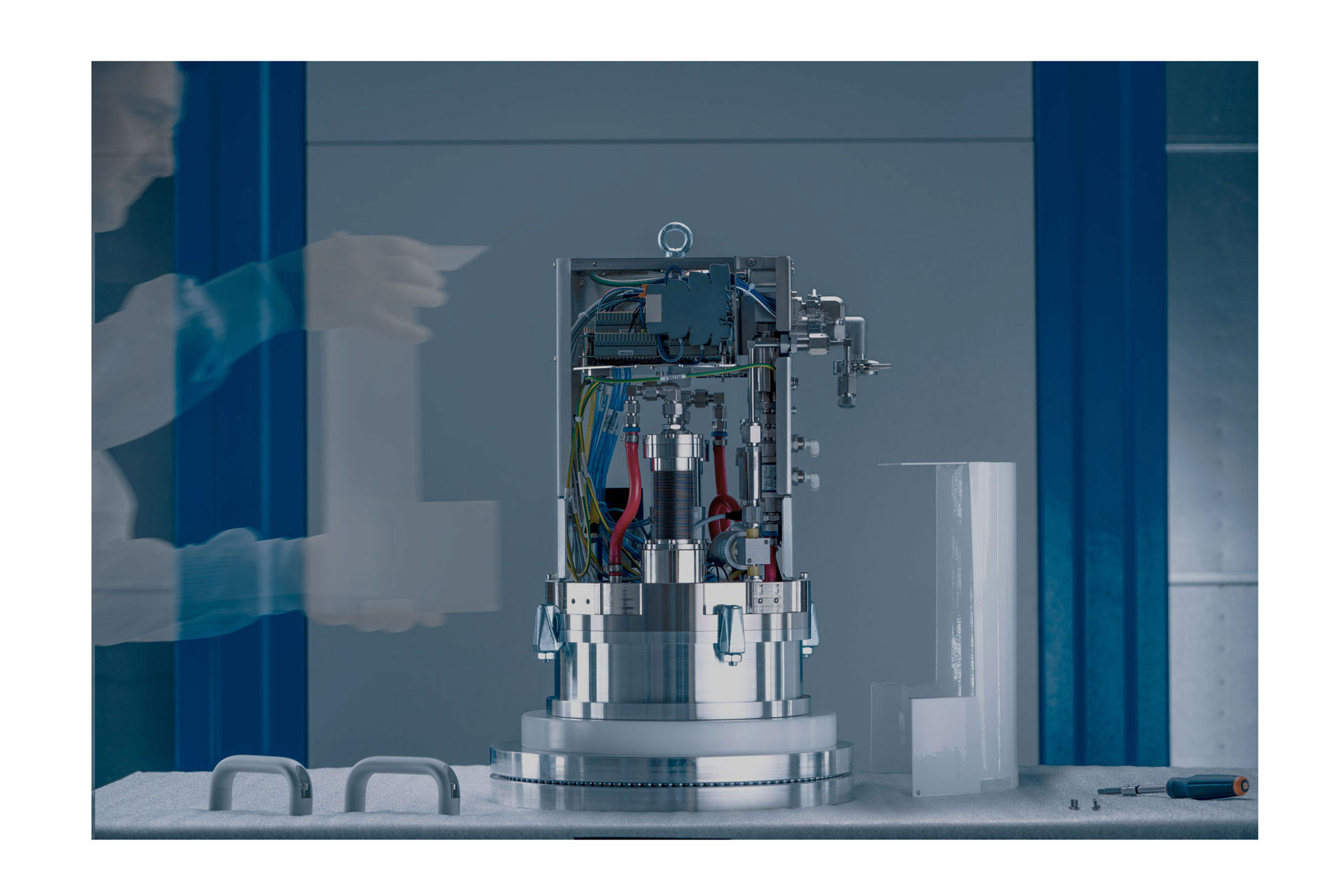

We use a fully automated ultrasonic cleaning system for the multi-stage cleaning process of the components. It is a 1-chamber, 3-bath system: A closed system in which all work steps from pre-cleaning to coarse rinsing, fine rinsing with deionized water (< 6 µS/cm) until drying takes place automatically under program control in a closed working chamber. The precisely defined process not only ensures the highest cleaning quality, but also a high throughput.

Immediately after cleaning / sterilization, the components go directly to the clean room, where they are only touched with clean, specially approved gloves. We implement the packaging process according to customer specifications; Sealing surfaces are protected with PE cover caps. Validated processes guarantee that only absolutely clean, residue-free components are delivered.