Mechanical processing

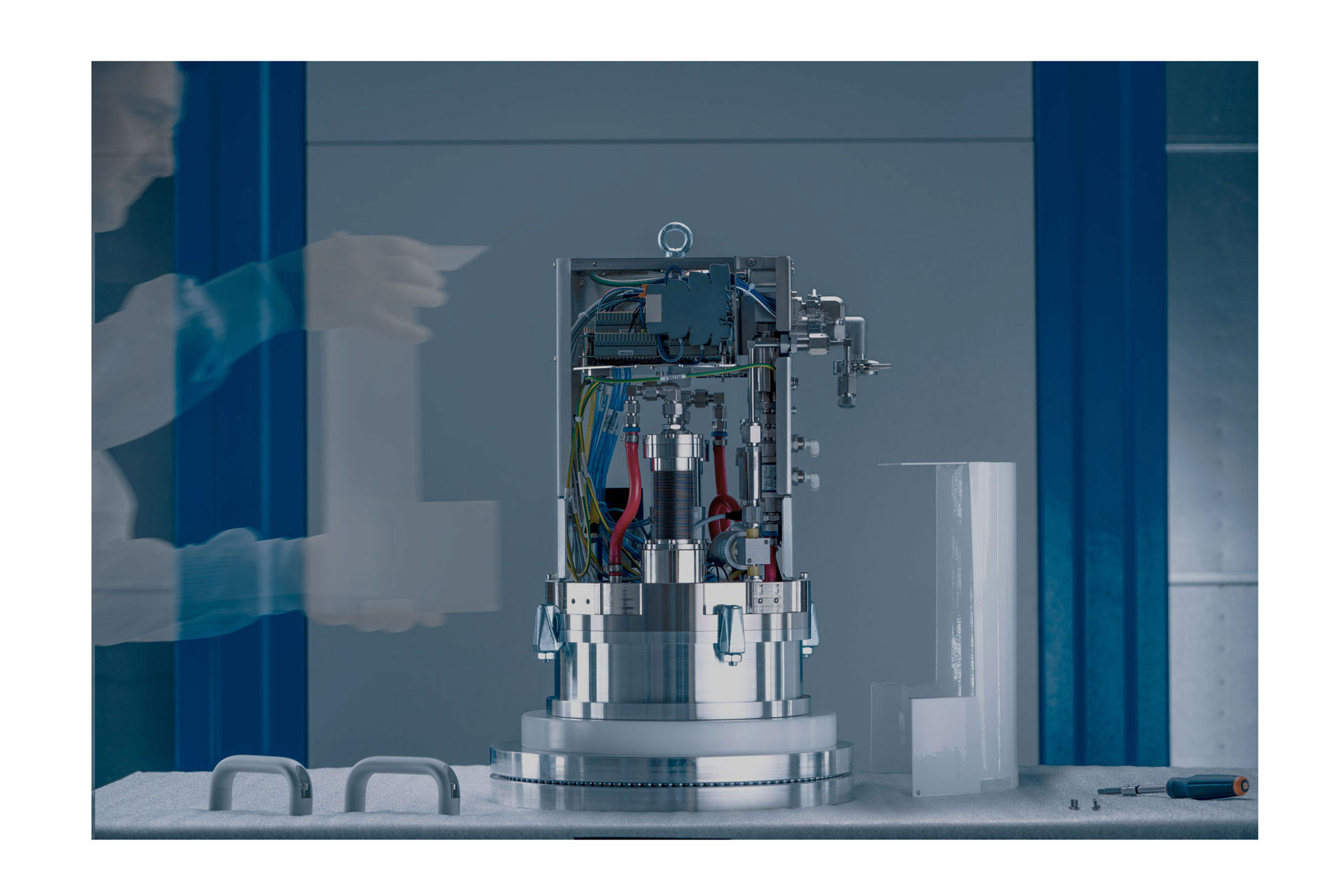

Many years of experience, a perfectly calibrated, partly automated machine park, validated processes, highly motivated and well-established teams that work across departmental boundaries are the basis for our consistently reliable performance. This makes us the right partner for the processing of series units and individually manufactured components of the highest quality and with optimized throughput times. Using CAM programming, we are also able to implement complex geometries.

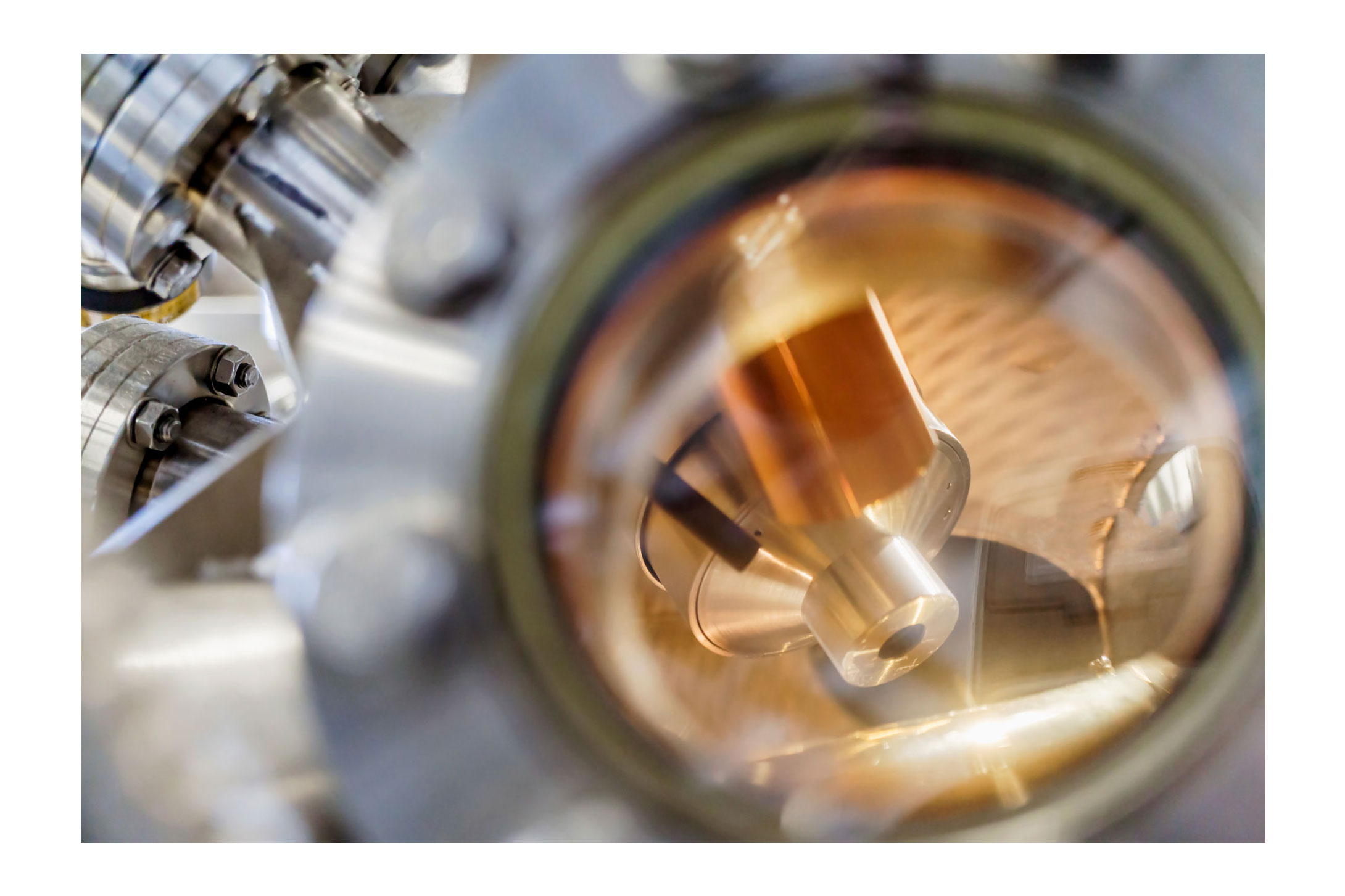

Turning and milling centers, horizontal and vertical machining centers and various CNC turning and milling machines with diameters from 5 to 700 mm are in use. In addition to machining titanium and CoCr alloys (cast and forged), various stainless steels and aluminum materials, copper materials and nickel-based alloys are also processed. Production includes individual parts for welded and soldered constructions as well as assemblies and high-precision, complex production parts. As a rule, the components are produced in small to medium series.

We use a variety of process technologies, including eroding, for example. We also manufacture complex geometric shapes, filigree contours, minimal radii and the tiniest of holes.