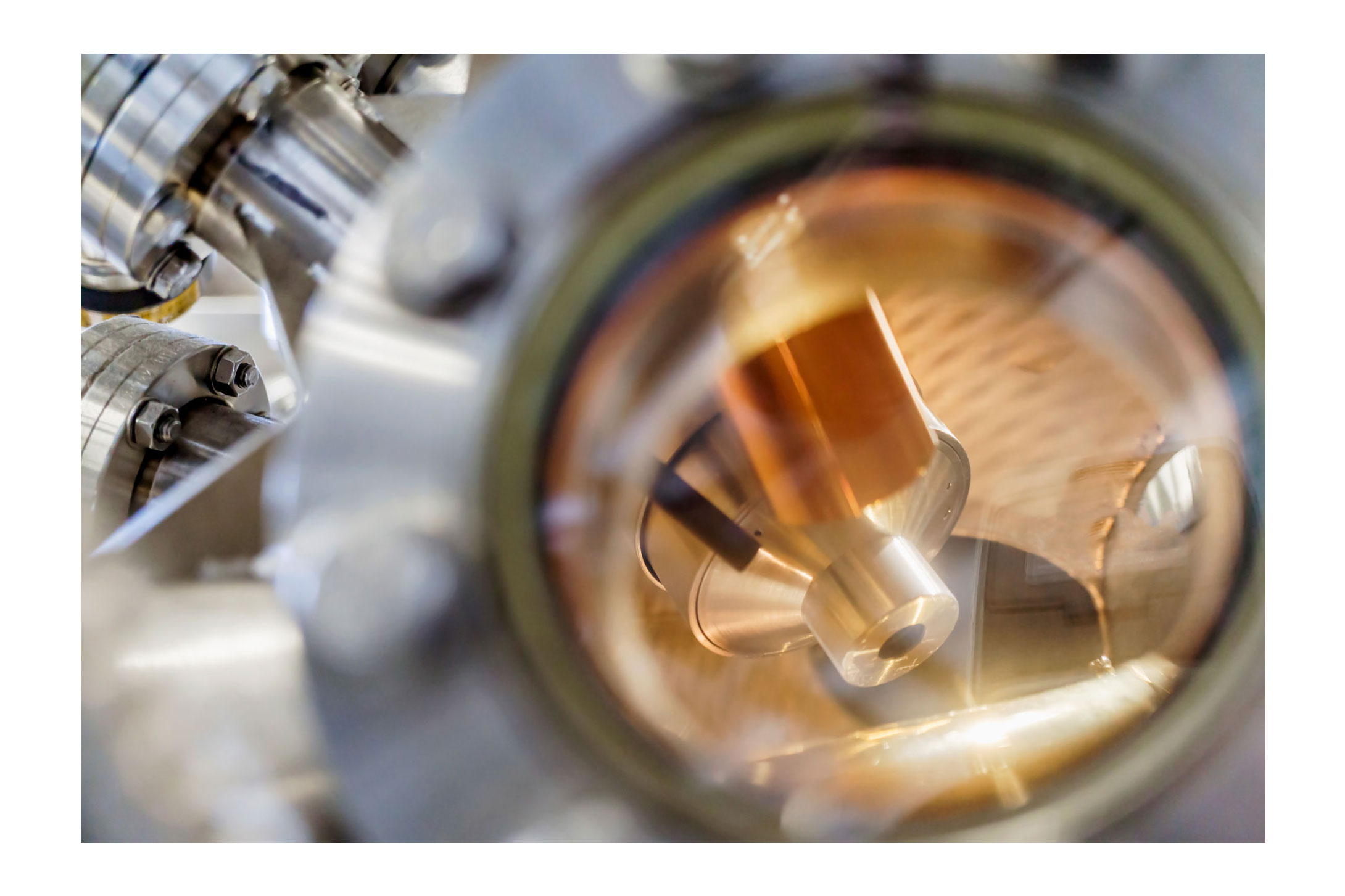

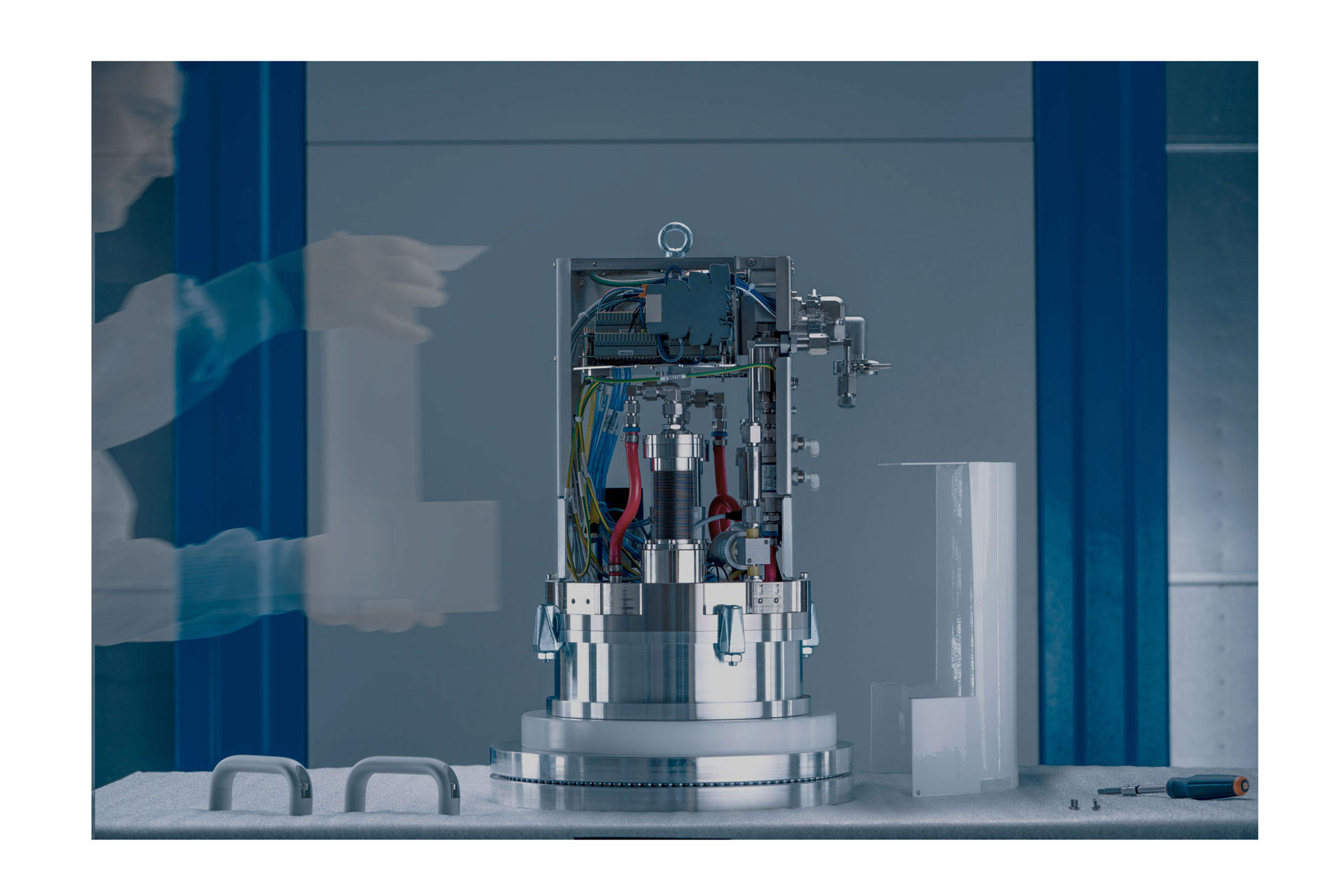

Immerse yourself in the world behind the scenes at SWACRIT systems and gain an insight into our daily activities. Our short video clip gives you a look behind the scenes and shows what it means to be part of our CREW. Experience how we work together to achieve our goals.

Jobfacts

38,5 h

per week.

- 2-shift operation in alternating shifts

- Early shift MO – FR

- 4-day week in the late shift: MO – DO

25 days

Vacation per year

> 40.600 €

annual gross amount. Overpayment depending on qualifications & experience. Collective agreement for the metal industry

WE ARE LOOKING FOR YOU TO SUPPORT OUR TEAM

Have you completed vocational training in the field of metal technology and ideally have several years of professional experience? Are you familiar with CNC controls and do you have experience in the external programming of machines (CAM)? Can you independently set up and run in jobs that have already been programmed and complete them to a flawless standard?

If working in two shifts suits your rhythm and you are also a team player, we look forward to receiving your application!

Your main tasks

- Programming, setting up and operating multi-axis CNC machines. Control: Heidenhain (milling), Sinumerik (turning), Fanuc & Sinumerik (turn-mill)

- CAM programming. We use the following software: TopSolid 7 (turning, milling & turn-milling)

- Monitoring production to ensure that the quality and accuracy of parts meet standards

- Measurement activities according to customer requirements or according to QP

- Carrying out maintenance work on machines and tools, provided they meet the qualification requirements

- Preparing and setting up machines and systems for processing

- Responsible for carrying out an orderly shift handover

- Identification and elimination of errors and deviations in the machining processes

- Documentation of work processes, deviations and results

- Stamping in/out of orders

- Cleanliness and cleaning of the workplace and tools

- Optimizing the machining process

- Compliance with work instructions, safety regulations and operational procedures