Quality control

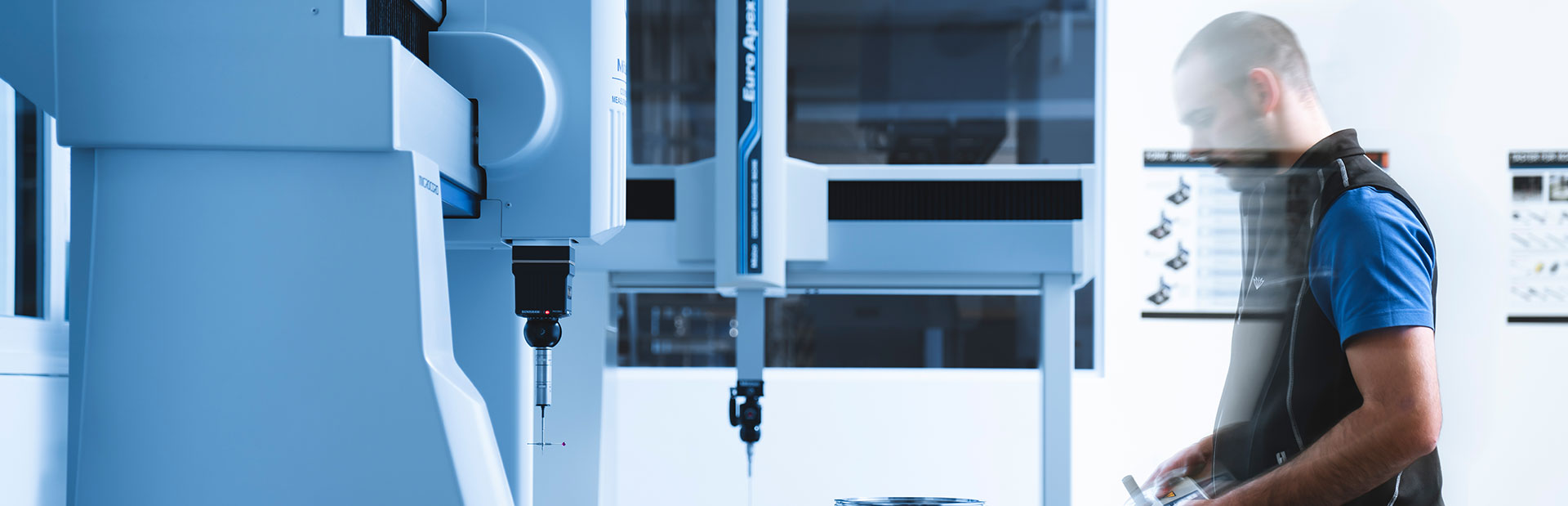

Reliable quality is the basic requirement for every company’s success. We live this quality standard every day: from the first inquiry through production to packaging and prove this through the use of modern computer-aided measurement technology.

In the area of dimensional and surface checks, 3D measuring systems and surface inspection devices are used in addition to the usual measuring equipment. Highly precise measurements are carried out by our experts in an air-conditioned environment.

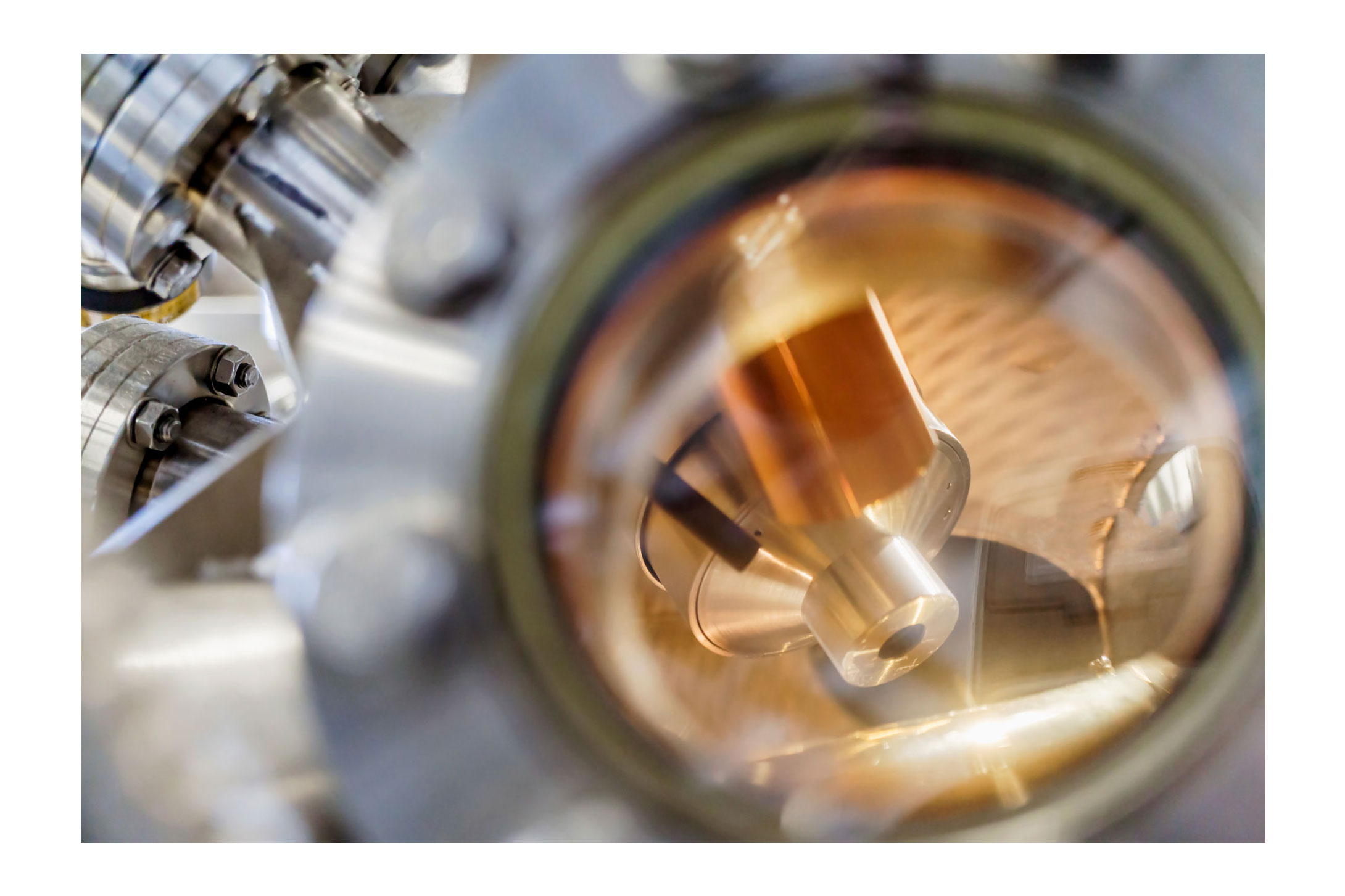

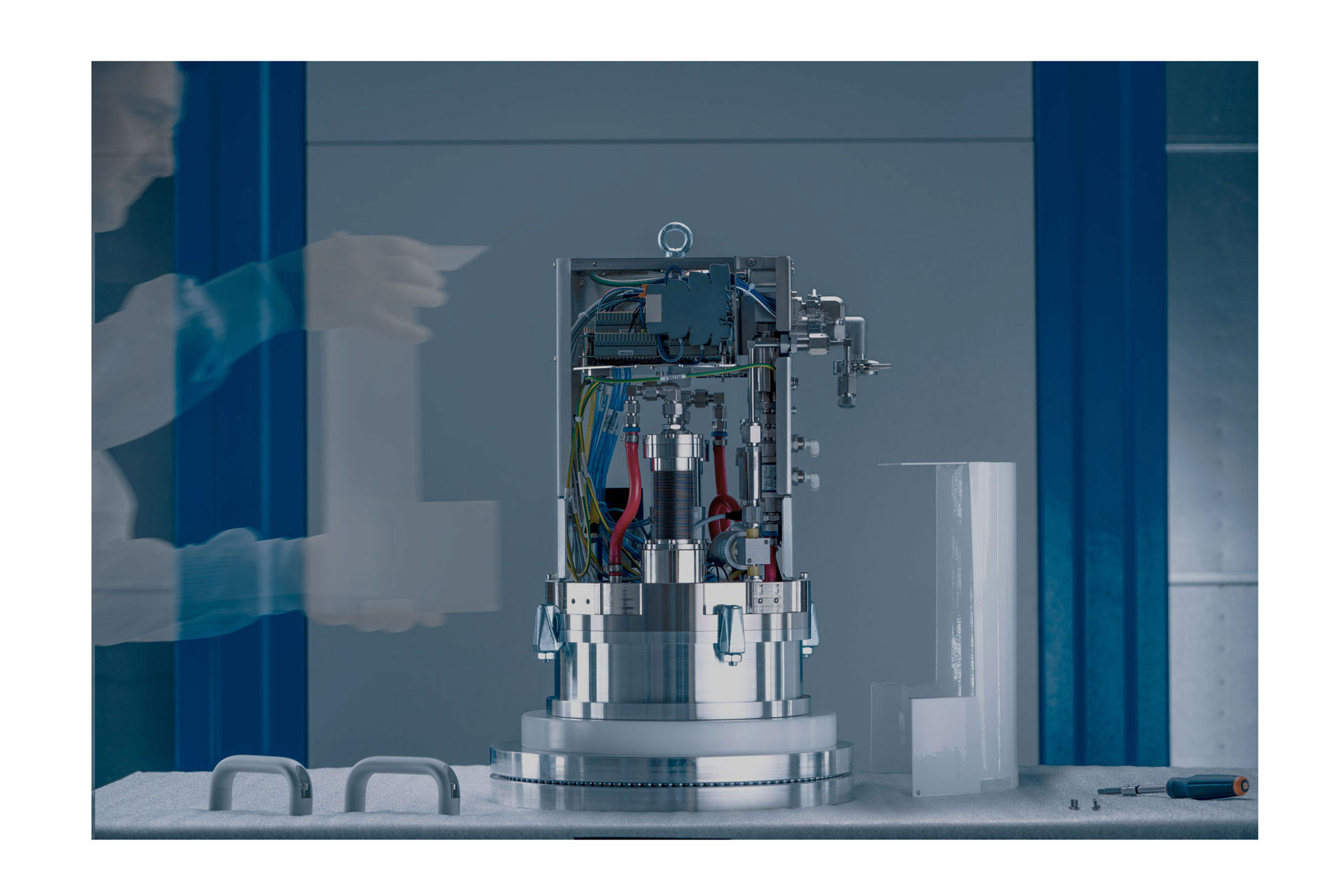

The processes used in joining technology must meet the highest standards. An essential quality feature is the reliable tightness, which we check with the appropriate leak detection method. The first step is to determine the desired tightness or leak rate, and then the right test method and test procedure are determined. The quality of the heat treatment is measured with hardness testers, for example. Magnetic properties can, for example, be measured and quantified using an in-house Remagraph.

For the tightness checks, we use He leak test devices up to a detection limit of 1×10-¹² mbar-l/s. This test method works particularly reliably even with the smallest of leaks, as the test gas helium can easily penetrate the vacuum and is reliably detected. For complete quality assurance, we carry out further analyses, such as pressure tests and flow rate tests. We guarantee process reliability and machine capability through regular monitoring. Internal and external audits are carried out regularly. We document all test procedures, so there is proof for all components. We also carry out the leak and pressure test in our clean rooms.