Clean room assembly in clean rooms

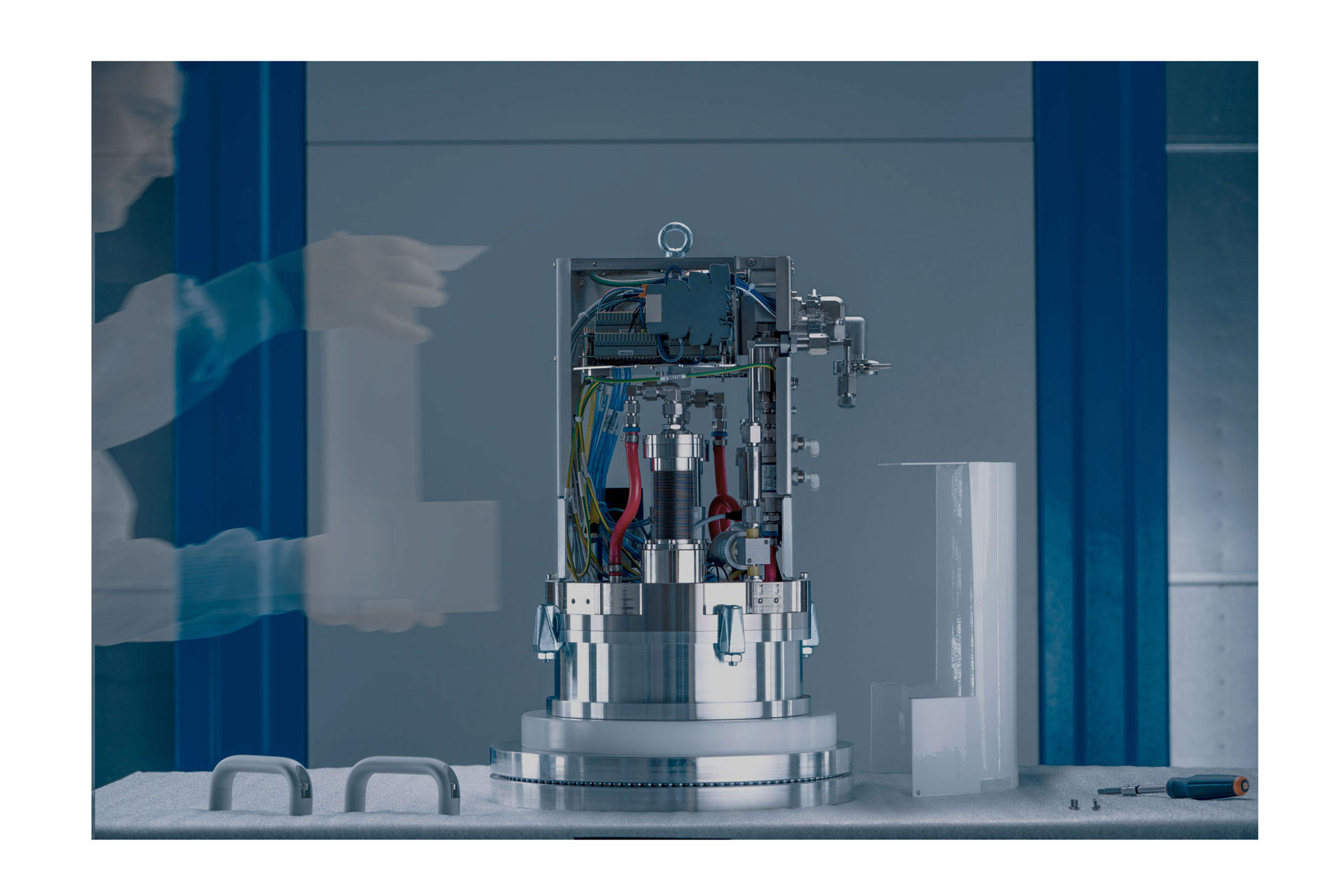

In our role as a system supplier, we are the strategic partner for complex system solutions. We have always relied on long-term partnerships and customer relationships. Our high level of vertical integration includes all common processes: in addition to providing advice from a manufacturing point of view, we support our customers right from the development and prototype phase and also take on the complete procurement of purchased components for the respective assembly.

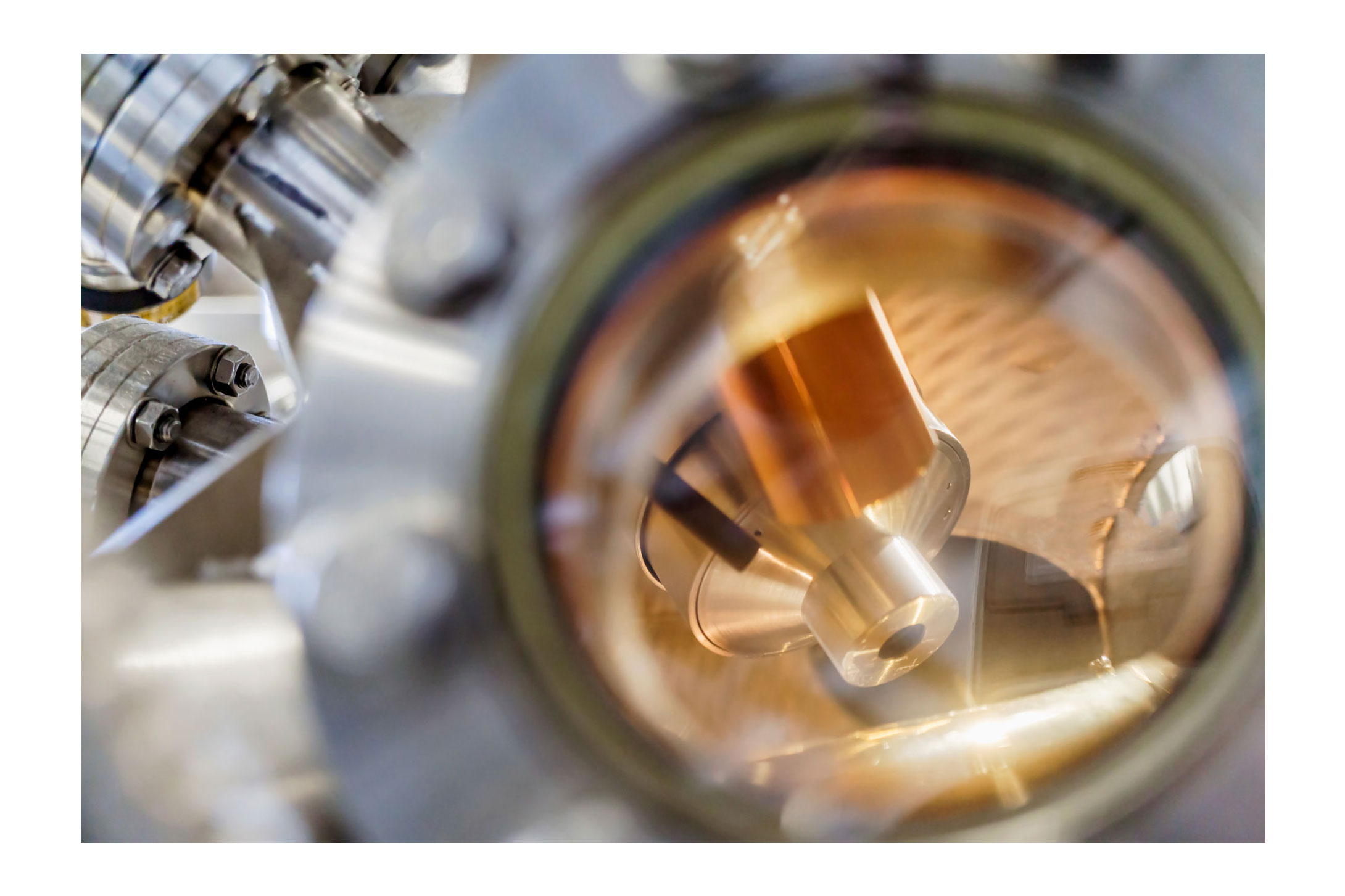

On a clean room area of 600 m² and a clean room area of 300 m 2 we assemble individual parts into complete assemblies and fabricate components. Depending on the requirements, we carry out functional and leak tests. Clean room specifications: sub-area up to ISO 6, main area ISO 7 – according to ISO 14644 “in operation”.

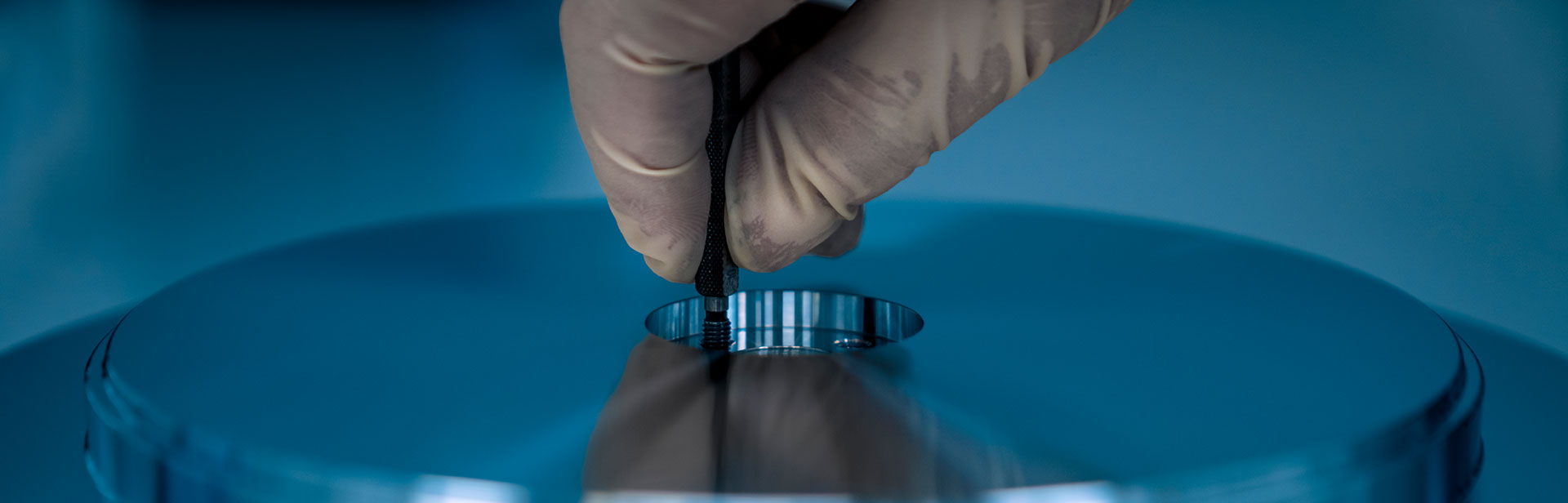

We have various assembly facilities at our disposal, which ensure that the assembly processes run with consistent quality and can be replicated in a stable manner. We guarantee cleanroom-compatible packaging and delivery with special equipment according to customer specifications. Validated packaging processes ensure compliance with the defined standards.

In the case of recurring components, the logistical processing is usually carried out via blanket orders with call-off, kanban system or individual orders.

A regular qualification of the clean rooms and the work equipment, comprehensive training of our employees as well as process-oriented, comprehensible work with full documentation are anchored in our quality management.