Surface processing

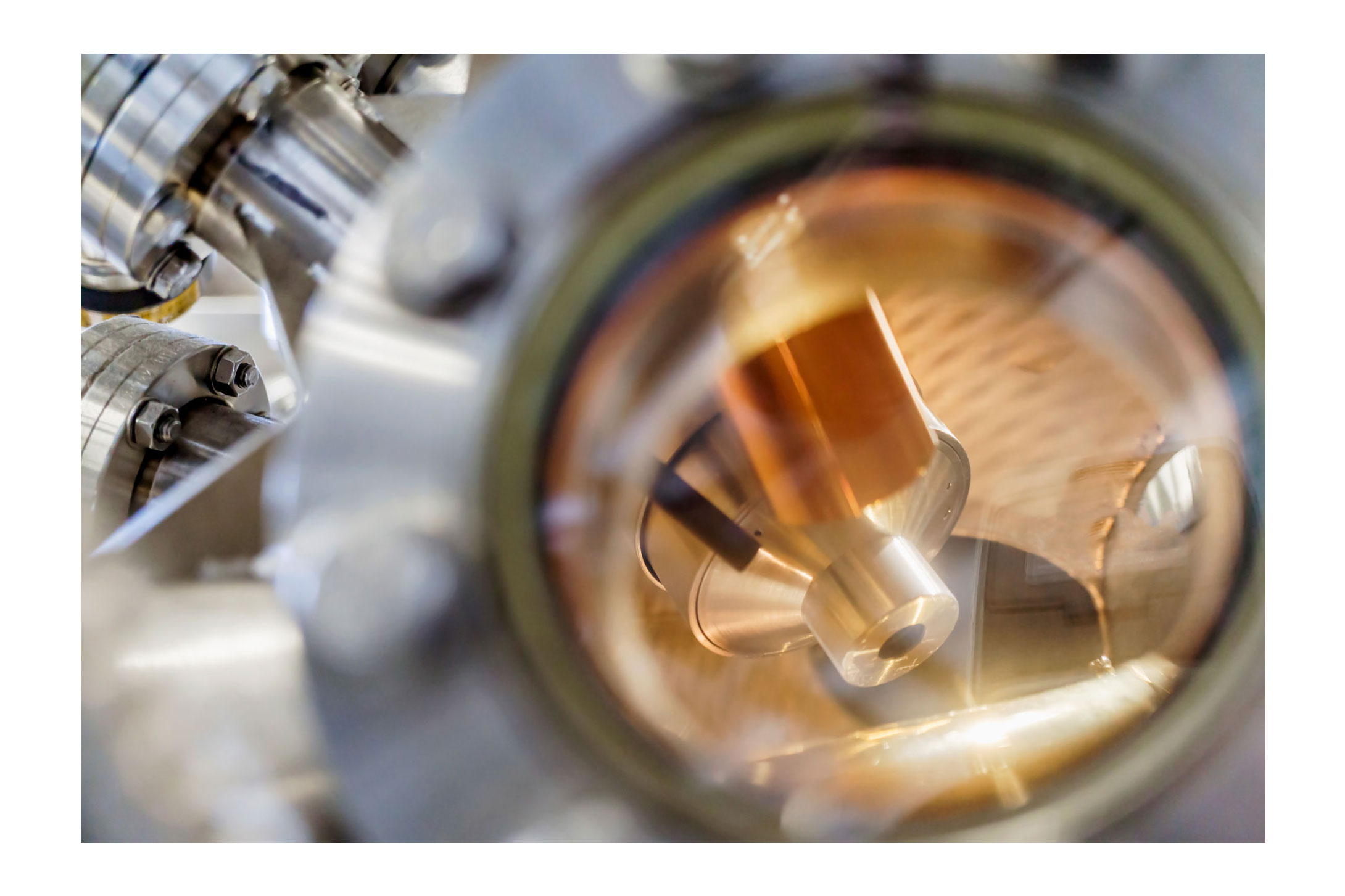

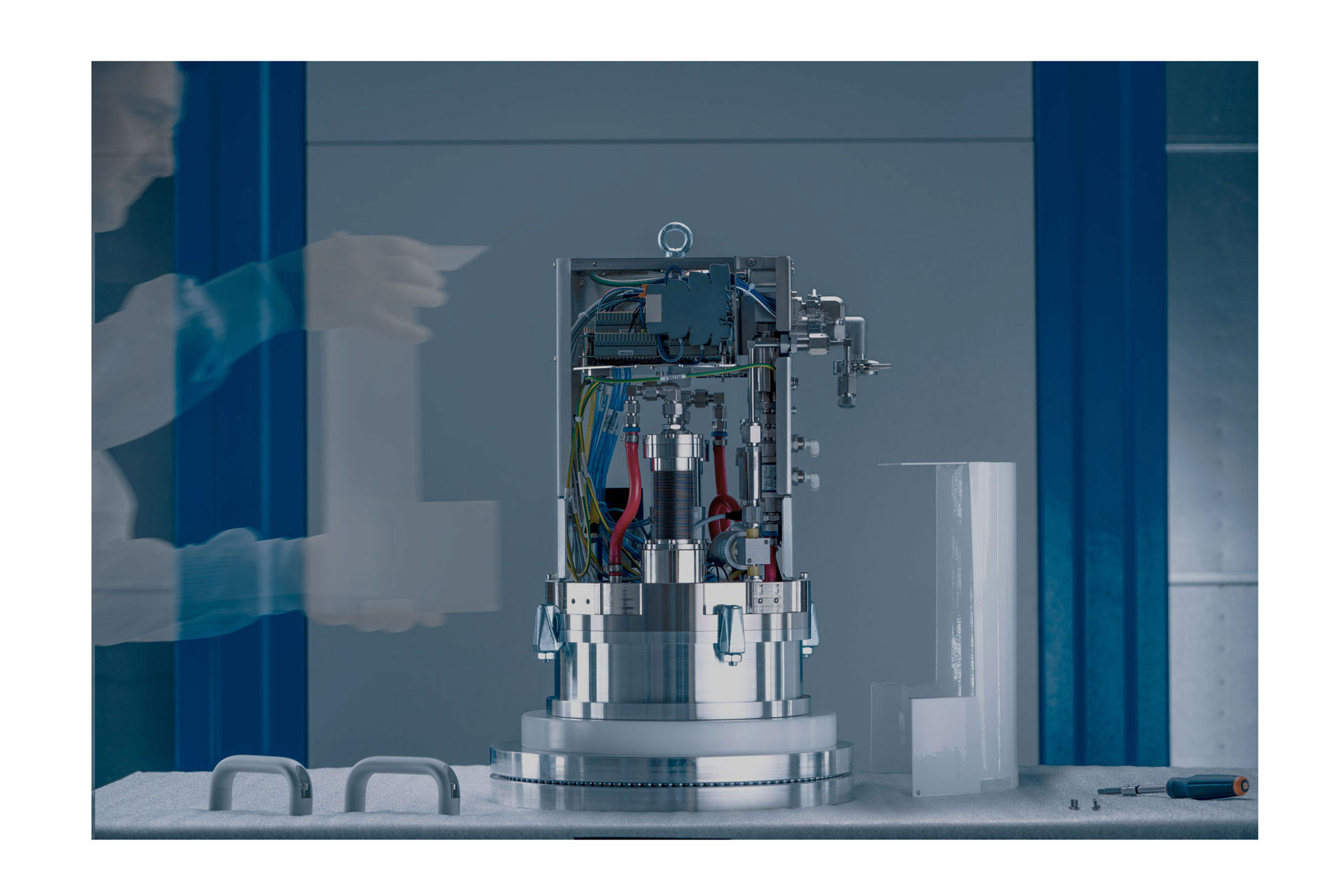

The absolute flawlessness of surfaces, sealing surfaces, reflecting surfaces (mirrors) and functional surfaces close to the beam is of utmost importance. For example, the internal surfaces of vacuum chambers and components are a decisive factor in achieving the working pressure in high vacuum and UHV. Therefore, after welding and mechanical processing, they are subjected to the appropriate treatment. Machining is performed with the objective of minimizing the effective surface area and producing surfaces with the lowest possible desorption rates. This applies to visible surfaces as well as to sealing surfaces.

Our expertise includes various solutions for the treatment of metal surfaces. We choose the method according to the pretreatment and the final application area. Special procedures are performed within our strong partner network.

Applied processes are for example corundum blasting, shot peening, ball peening, (electro) polishing, barrel finishing.